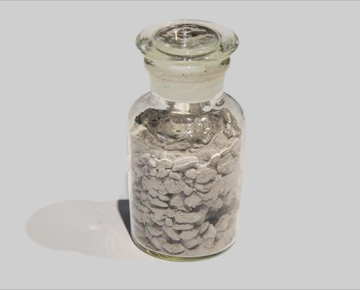

Neutral ramming mass used for induction furnace with much higher service life than silica ramming mass, which can save cost for customer evidently

Induction furnace neutral ramming mass is a cost-effective dry vibrating refractories composed of special grade clinker clinker, corundum, spinel, magnesia and sintering agent. Such ramming mass is suitable for the melting of carbon steel, alloy steel, stainless steel and high manganese steel, with high service life and high cost performance. Induction furnace neutral ramming mass is used by many foundry companies and steel plants because of achieving low cost and long life with good performance.

◆Steel plant induction furnace

When using ramming mix in induction furnace, the neutral ramming mass performs much longer service life comparing with silica ramming mass, which can save much labor time and furnace baking time, thus can save much money for steel plants.

◆ Additives a, longer and stable service life to get high efficiency

◆ Easy to be installed and maintenance, saving time and labor cost

| Material | Bauxite-spinel |

| AL2O3/% | ≥72 |

| MgO,% | ≥18 |

| Bulk density g/cm3 | ≥2.8 |

| Normal use temperature/℃ | 1600~1650 |

| Use upper temperature limit (short time)/℃ | 1700 |

| Maximum granularity/mm | 5 |

Submit Request

PDF Request