Ceramic fiber blanket working temperature is 900-1400 degree according to different quality level. The size is customized.

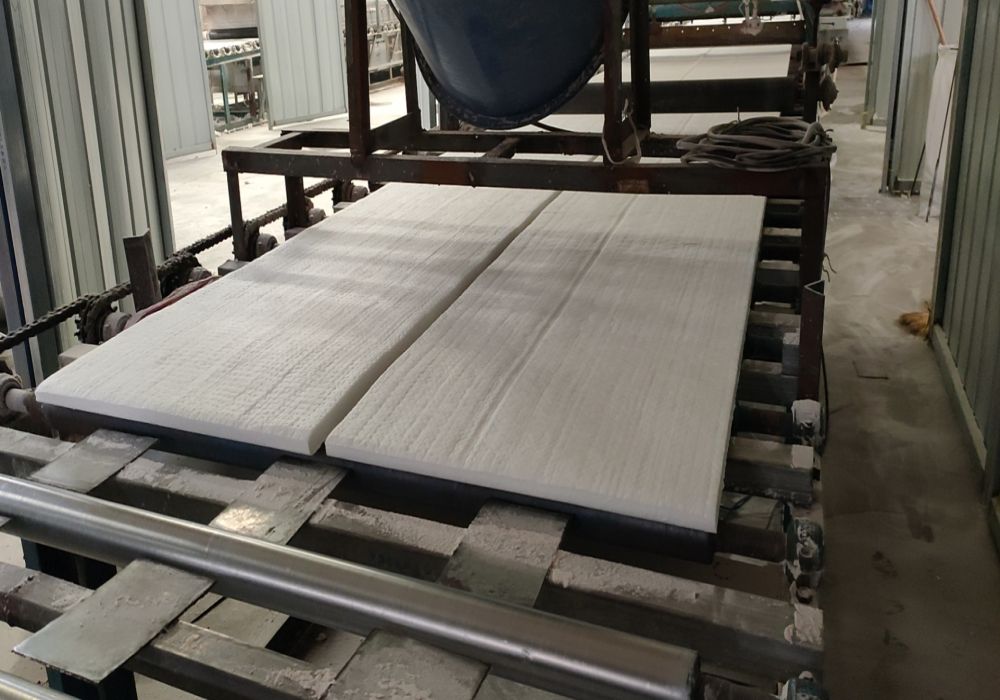

Refractory ceramic fiber blanket is one kind of new refractory fiber products made by needling blanket making process. White color, regular size, low bulk density, low thermal conductivity, easy cutting and installation, and chemical stability are its characteristics. It can widely be used as lining for kiln and furnace, and insulation layer for high temperature pipe.

The ceramic fiber blanket manufactured by CH Refractories is characterized by superior chemical stability, low heat loss, superior resistance to thermal shock, good acoustic and thermal insulation. Multiple choices on density and dimension prop up the fine insulating performance in various industrial applications.

◆High temperature industrial kiln insulation

◆Lightweight and low thermal conducitivty

◆High working temperature resistance and insulation

◆Superior strength for easy installation and maintenance

◆Low fiber shot contents and high resilience

◆Low heat storage for high efficiency enery savings

◆Can be foled, compressed for modules or blocks as insulation

| Product Brand | XWT40 | XWT45 | XWT48 | XWT50 | XWTZ15 |

| Material | Aluminum silicate | High alumina | Zirconia | ||

| Al2O3% | 40-44 | 44-46 | 46-50 | 50-60 | 30-35 |

| Al2O3+Si02% | ≥94 | ≥96 | ≥97 | ≥97 | ≥987(+Zr02) |

| ZrO2% | - | - | - | - | ≥15 |

| Fe2O3% | ≤1. 2 | ≤1.0 | ≤0.8 | ≤0.5 | ≤0.5 |

| Na2O+K2O% | ≤0.5 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 |

| Service temperature/℃ | ≤1000 | ≤1000 | ≤1100 | ≤1200 | ≤1350 |

| Volume density/kg.m3 | 95~160 | 95~160 | 95~160 | 95~160 | 95~160 |

| Thermal conductivity/W(m.k) | ≤0.14(600℃) ≤0.18(800℃) | ≤0.14(600℃) ≤0.18(800℃) | ≤0.18(800℃) ≤0.22(1000℃) | ≤0.18(800℃) ≤0.22(1000℃) | ≤0.22(1000℃) ≤0.28(1200℃) |

| Heating shrinkage/% | ≤3 (800℃,24h) | ≤3 (1000℃,24h) | ≤3 (1100℃,24h) | ≤3 (1200℃,24h) | ≤3 (1300℃,24h) |

| General size | 7200mmX600mmX12(20,25,40,50)mm | ||||

Submit Request

PDF Request