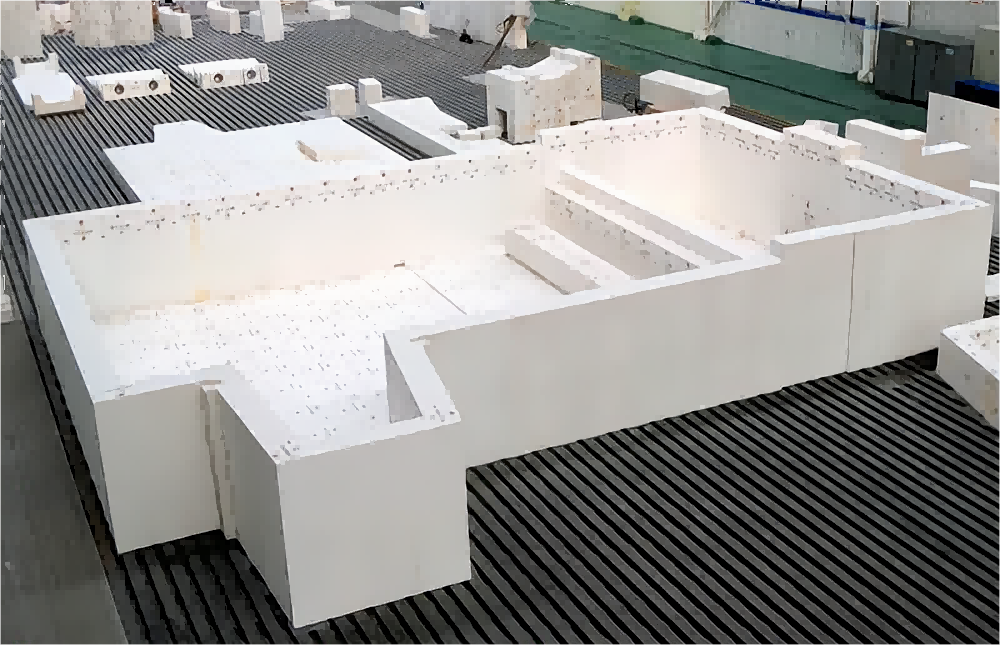

CH Refractories manufactured AZS Block with very good performance and competitive price. we will do pre-masonry before delivering for every order

Zirconium corundum brick is also named AZS brick. It is based on three chemical components of the Al2O3-ZrO2-SiO2 ternary phase diagram and widely used for glass kiln. The glass kiln brick is arranged according to the order of its contents. Al2O3 takes A, ZrO2 takes Z, and SiO2 takes S. The national standard uses this abbreviation. For example, No.33 cast zirconia corundum brick, abbreviated as AZS-33#, No. 36 cast zirconia corundum brick, abbreviated as AZS-36#, No. 41 cast zirconia corundum brick, abbreviated as AZS-41#.

AZS-33# Brick to prevent contamination of glass liquid is particularly superior, it causes stones in glass, bubbles and basic glass phase precipitation trend is very small. It is suitable for the upper structure of the glass melting pool, the wall brick of the working pool, the paved brick and the material channel.

AZS-36# Brick is a standard zirconia fused zirconium corundum brick, which has the characteristics of high corrosion resistance and low pollution resistance of glass liquid, and the performance in these two aspects is balanced. The fused cast AZS brick is suitable for the parts in the glass furnace which are in direct contact with the glass liquid, such as the wall brick of the melting pool, the paving brick, the feeding port and so on.

AZS-41# brick is very high-grade zirconia fused zirconium corundum brick, it has very high corrosion resistance of glass liquid and outstanding low pollution to glass liquid. It is suitable for the parts with high corrosion resistance in glass kiln, such as full electric furnace, fluid hole, kiln, bubble brick, brick at the corner of feeding, etc.

According to different applications, CH Refractories provide four casting methods for AZS refractory glass kiln bricks, which are:

PT-normal casting, the shrinkage cavities of bricks are formed under the casting gate; QX-tilt casting, the shrinkage cavities of bricks are located at bottom side while a complete dense zone forms at the opposite end; ZWS-ending casting, this casting method is similar with“WS”, merely a few shrinkage cavity remain in upper part of the brick; WS-void free casting, no shrinkage cavity left in brick.

CH refractories will make AZS Brick pre-building for each order carefully before delivering.

◆Widely be used for linings of furnace in glass industries.

◆Erosion resistance. Ultra low apparent porosity

◆High strength and high compression resistance

◆Thermal shock resistance and erosion resistance

◆Performance in high temperature, good thermal conductivity

◆Free sample,Free construction guidance ,free 3D design

◆Customerize mould according to different size requirements for free

◆Caihua refractory company manufactured azs bricks with very competitive price comparing with other suppliers in China.

| Brand | AZS33-Y | AZS36-Y | AZS41-Y | |

| Chemical compostion% | ZrO2 | 32-36 | 35-40 | 40-44 |

| SiO2 | ≤16.00 | ≤14.00 | ≤13.00 | |

| Na2O | ≤1.45 | ≤1.45 | ≤1.30 | |

| Fe2O3+TiO2+CaO+MgO+Na2O+K2O | ≤2.00 | ≤2.00 | ≤2.00 | |

| Fe2O3+TiO2 | ≤0.30 | ≤0.30 | ≤0.30 | |

| Bulk density g/cm3 | ≥3. 75 | ≥3. 80 | ≥3. 95 | |

| Apparent porosity | ≤1.5% | ≤1.0% | ≤1.0% | |

| Staticanti-corrosion rate of glass liquid, mm/24h (normal soda-lime glassmeglass,1500℃x36h) | ≤1.50 | ≤1.40 | ≤1.30 | |

| Exudation temperature of vitreous phase | ≥1400℃ | ≥1400℃ | ≥1400℃ | |

| Bubble precipitation rate (normal soda lime glassmeglass,1300℃x10h)) | ≤2.0% | ≤1.5% | ≤1.0% | |

| Vitreous phase seepage amount(1500°Cx4h) | ≤2.0% | ≤3.0% | ≤3.0% | |

| Volume weight, g/cm3 | PT、QX | ≥3. 45 | ≥3. 45 | ≥3. 55 |

| ZWS | ≥3. 60 | ≥3. 70 | ≥3. 85 | |

| WS | ≥3. 70 | ≥3. 80 | ≥3. 95 | |

Submit Request

PDF Request