There are many kinds of acid-resistant bricks on the market. According to the bulk density, there are light acid-resistant bricks and heavy acid-resistant bricks, and they are divided into high temperature acid-resistant bricks and low temperature acid-resistant bricks according to the service temperature. According to the thickness is divided into acid-resistant tiles and acid-resistant standard bricks, no matter which form of acid-resistant bricks, the main components are silica.

Acid-resistant ceramic tile is literally a kind of ceramic tile, its main component is silica, which forms a large number of aluminum andalusite under high temperature roasting, which is a substance with high acid resistance. Due to the tight structure of the acid-resistant brick and the small water absorption rate, it can also withstand any concentration of alkaline media at room temperature, but it is not resistant to high temperature molten alkali. The acid-resistant brick contains more than 70% silica and is sintered. It is widely used in the chemical industry in acid ditch, acid well, acid storage and affected ground with large acid load. The thickness of acid-resistant tile has 15 20 30 45 65 and other subdivided plain surface, sub-glaze, full glaze, etc., the use temperature does not exceed 200℃ water absorption rate ≤0.5% bending strength ≥39.2MPA, acid resistance ≥99.8%,

The sintering temperature of acid-resistant firebrick is above 1100℃, the use temperature is at 900℃, its use performance is more stable, the light acid-resistant brick is generally about 1.3g/cm3, the normal temperature pressure is 8-10MPA, the acid resistance is above 95%, the heavy acid-resistant brick's body density is between 2.0-2.3, and the acid resistance is more than 98%-99%. The lower porosity is generally 12-13, the normal temperature pressure is above 65mpa, and the water absorption is less than 6%.

In summary, the selection of acid-resistant bricks depends on the actual use of the site, the service temperature, pressure, bulk density requirements, and so on to make the final choice.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

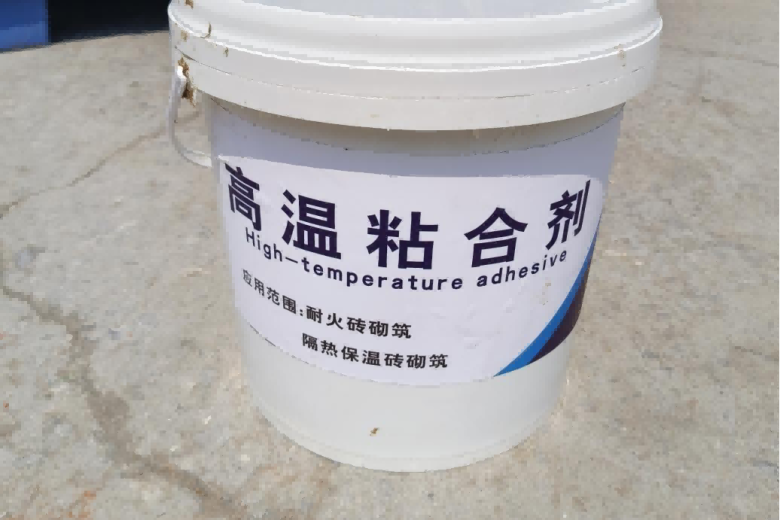

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request