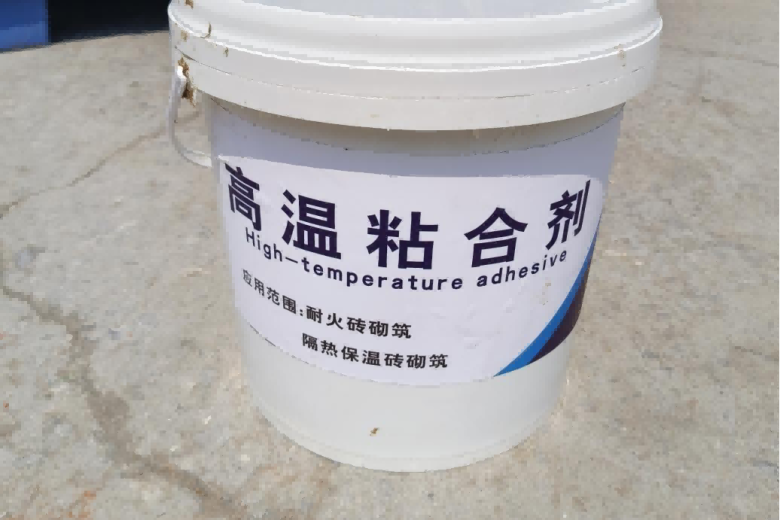

The types and functions of high temperature adhesives

Can silicon-magnesia red bricks be used as the inner lining of lithium ash kilns?

The appearance color of fire clay brick just means that the appearance of the surface of the brick is beautiful, and the aluminum content has a…

The amount of water adding should be strictly controlled during construction of ultra-low cement castable Ultra-low cement castable is a kind of high-grade refractory castable, the…

Intermediate frequency furnace is a kind of equipment widely used in metal melting, the high temperature resistance of its lining material is directly related to…

High aluminum bricks belong to the neutral series of firebricks, because of different aluminum content, there are different levels, but at present, the severe situation…

Welcome Thailand customer visit our factory to check the rotary kiln bauxite cargo and production process, CH Refractories bauxite output every month over 20000tons, can…

Rotary kiln products have cement, white ash, zinc smelting rotary kiln, as well as alumina, nickel and other rotary kiln. The proportion of rotary kiln used…

Submit Request

PDF Request