Refractory castable drying and baking control process

The difference between silicon brick and semi-silicon brick

The main defects in the production process of refractory bricks are underburning, overburning, damage, contamination, core encirclement, distortion, cracking, etc. Underfiring is a problem caused…

Refractory clay is the main raw material for the production of aluminosilicate refractory materials. All kinds of hard clay, soft clay, semi-soft clay and clay…

Anti-skinning castable is made by adding silicon carbide aggregates and powder to the low-cement castable, then adding high-efficiency water reducing agent and ultrafine powder, and…

Every country have different definition of refractory materials. According to international standards, refractory materials are defined as non-metallic materials and products whose chemical and physical properties…

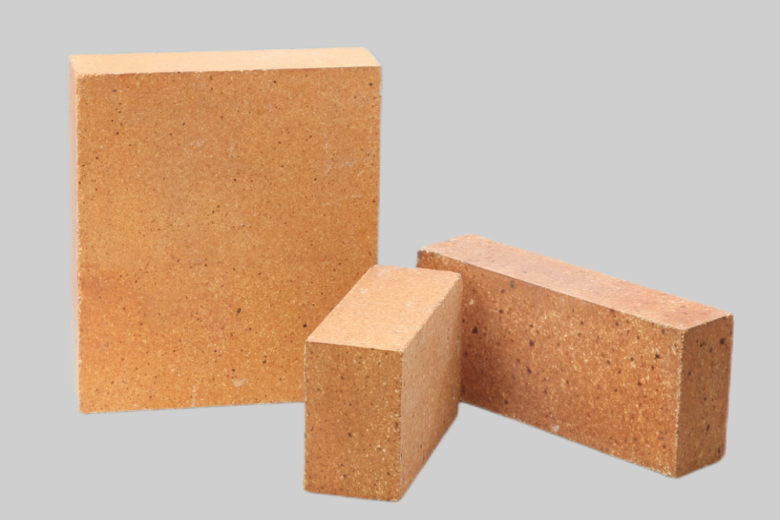

Clay brick is made by clay clinker and soft clay as a bond aluminum content of 30-48% stereotyped refractory. The particle composition of clay brick…

Under normal circumstances, the calcination belt uses bricks with a body density of more than 2.9, the transition belt uses 2.6 body density of ordinary…

Submit Request

PDF Request