The refractory ramming material is divided into acid, neutral, alkaline, carbon, etc., according to the material category, there are clay, high aluminum, mullite, corundum, silicon, magnesium, silicon carbide, mullite corundum and so on. The binder is combined with water glass, phosphoric acid, phosphate, aluminum sulfate, brine, high aluminum cement, clay and other different ways.

Refractory ramming material chemical stability is good, erosion resistance, wear resistance, heat shock, carbon type material is generally used in the temperature of more than 1500℃ above the bottom of the furnace use, even 2200℃ can be used, such as blast furnace and calcium carbide furnace bottom are used this ramming material.

Neutral ramming materials, such as high aluminum, corundum ramming materials are used for the use of neutral atmosphere furnace lining, for filling the gap between the furnace cooling equipment and the masonry leveling layer.

Both alkaline and acidic ramming materials are used in the medium frequency furnace, if the smelting iron material, the acid ramming material is used, if the smelting steel material, the basic magnesium ramming material is used. There are also intermediate frequency furnace linings for iron and steel training, and magnesium ramming materials are used.

The acid ramming material is made of silica and can be used as the filling material for the sulfuric acid tower. It can also be used in intermediate frequency furnace lining.

The moisture content of the refractory ramming material is low, and the ramming is strong, and the performance is better than the refractory castable. However, the disadvantage of ramming materials is that the construction speed is very slow and the labor intensity is large.

The refractory ramming mass materials types are no more than refractory castable, but the application effect of the small blast furnace iron ditch skim and branch ditch, slag ditch is indeed better than the performance of refractory castable, with the actual use of the market continues to evolve, ramming materials also have the direction of continuous technical improvement, such as composite ramming materials, it is suitable for use in the case of complex lining atmosphere.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

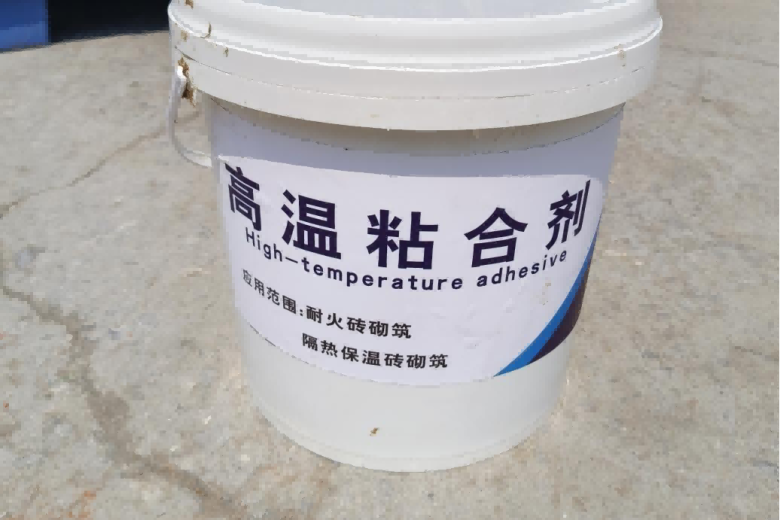

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

The light and heavy composite high alumina brick integrates the functions of the two layers of refractory bricks that need to be laid for the…

Submit Request

PDF Request