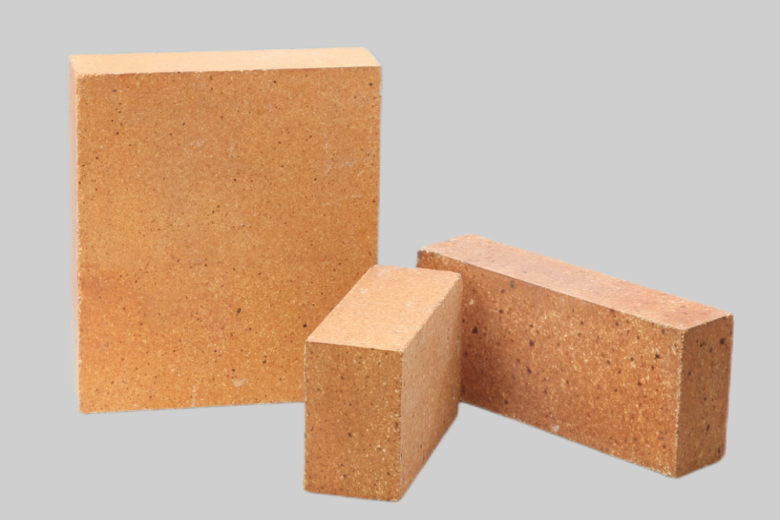

The lining of the molten iron tank is made of firebrick in different materials, such as clay brick, high-aluminum brick, low-porosity brick. And about the three cans, mainly use aluminum silicon carbide carbon brick.

The cycle is different according to firebrick material. Under normal circumstances, the use of clay bricks is more, but although the cost of clay bricks is low, the shortest number of uses is between 300-500 times, if the use of high aluminum bricks or low porosity bricks, the number of uses is 600-800 times, if the use of aluminum silicon carbide carbon bricks, the number of cycles is 1200-1400 times.

In addition, there are all the use of refractory castable can lining. The use of refractory castables is strong in air tightness, but there must be a special birthware, and a special baking device, the early cost will be high, and there must be a certain cost for making birthware and baking device. The use of refractory castables is also based on different quality, the service cycle is also different.

There is also a mixture of the two, the mixing scheme is the use of low porosity brick or aluminum silicon carbide carbon brick on the tank wall, the permanent layer of the tank bottom or the working layer are used refractory castable, this mixed use has its advantages, that is, when the tank bottom maintenance, you can save the lining of the permanent layer, the old lining can be used to reduce production costs. And the old lining is not like the low porosity brick bottom, which needs to be levelled before making the tank bottom lining, and when the castable makes the tank bottom lining, what kind of situation can be delayed and then used as castable.

If the lining of the tank all use aluminum silicon carbide carbon bricks, the permanent layer of the bottom of the tank is also mostly used refractory castable, the working layer is selected circular brick, and the wall of the tank is laid with various types of aluminum silicon carbide bricks, because according to the design of a variety of brick types, the entire lining will not be wrong, and the service cycle of the tank lining will be relatively extended.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 13721425142

Clay brick is made by clay clinker and soft clay as a bond aluminum content of 30-48% stereotyped refractory. The particle composition of clay brick…

Under normal circumstances, the calcination belt uses bricks with a body density of more than 2.9, the transition belt uses 2.6 body density of ordinary…

Submit Request

PDF Request