Refractory cement is also known as high temperature cement, high aluminum cement, aluminate cement, etc., natural high quality bauxite and high quality lime as raw materials, according to a certain proportion, through high temperature sintering (or through electric furnace melting) and mature material, aluminate as the main component of the clinker, and then ground into fine powder, made with fire resistance of hydraulic cementing material, known as refractory cement. The refractoriness of refractory cement is not less than 1580 degrees Celsius, and the main mineral phase is calcium aluminate (CA) and calcium aluminate (CA2).

Refractory cement is widely used in the refractory industry, especially in amorphous refractory materials, as a major hydraulic binder, with good high temperature resistance, stable setting time, high strength characteristics, Often we take the initial setting time, final setting time, 6-hour flexural strength, 24-hour flexural strength, 72-hour flexural strength, 6-hour compressive strength, 24-hour compressive strength, 72-hour compressive strength, etc. as an important basis for judging whether a cement is qualified.

The main chemical composition of refractory cement is aluminum oxide and calcium oxide, but in the application process of refractory industry, calcium oxide is a material in some sense, so the addition of refractory cement in amorphous refractory material is crucial, such as some low cement castable, it is necessary to strictly control the addition of refractory cement, usually 1%-3%. However, there are some rich cement castables, and the addition of refractory cement of these castables is usually between 10% and 20%. For different castables, different conditions of use, the type of refractory cement selected is different, of course, the amount of addition is naturally different.

Excellent quality refractory cement plays a vital role in the use of amorphous refractory materials, inferior products directly determine whether the castable can be used normally, but now some bad businesses, in order to reduce costs to maximize profits, use unqualified raw materials, reduce the content of refractory cement aluminum oxide, The initial setting time and final setting time are seriously inconsistent with the national standards, the folding strength and compressive strength are greatly reduced, and some businesses in order to achieve chemical indicators, add other substances (laundry detergent, building cement, etc.) to increase the content of aluminum oxide, although the chemical indicators can meet the national standards, but the mineral phase in refractory cement does not meet the standards. The bending strength and compressive strength do not meet the requirements, resulting in safety production accidents, so the selection of refractory cement has an important position in the amorphous refractory material.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

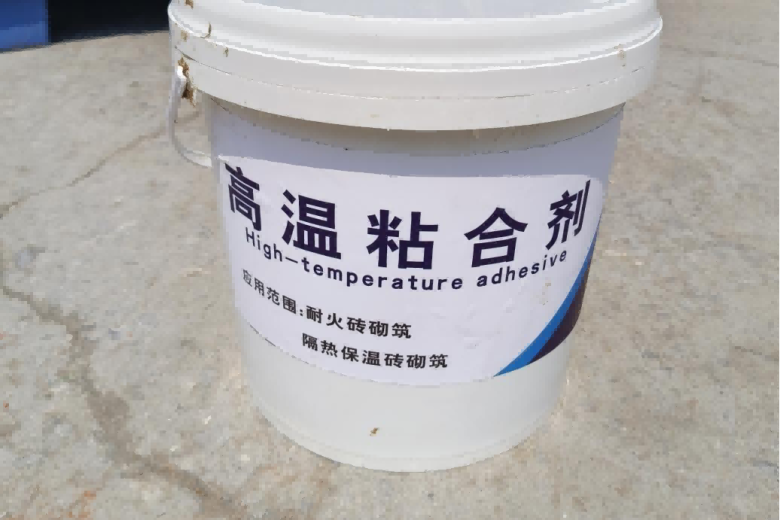

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request