Rotary kiln products have cement, white ash, zinc smelting rotary kiln, as well as alumina, nickel and other rotary kiln. The proportion of rotary kiln used for firing ceramics is not very large.

Ceramic rotary kiln is also divided into three types: one is the rotary kiln for firing oilfield proppant ceramics, the second is the rotary kiln for shale ceramics, and then the rotary kiln for sludge ceramics, but the rotary kiln of these three materials is generally not large.

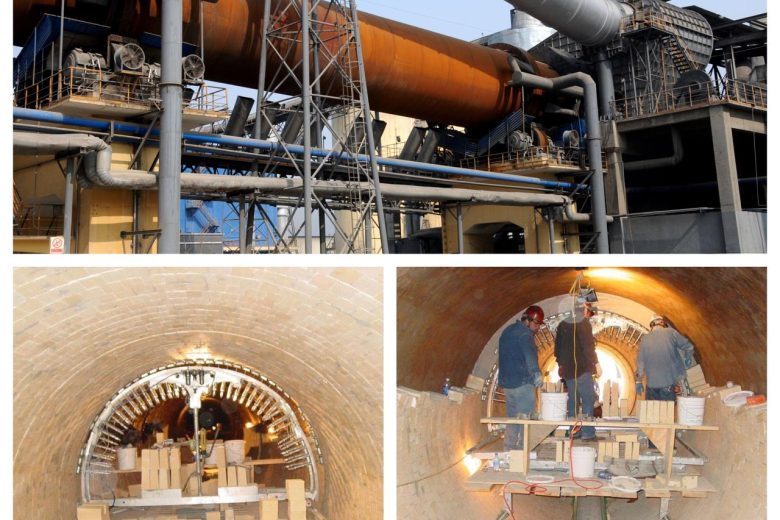

The oil field proppant ceramic is used in rotary kiln, temperature is 1400℃, the burning belt is generally selected special phosphate brick (body density is 2.85-2.9 can be used), and the phosphate brick of composite material can be used, and the burning belt is preferably not less than 25 meters. The transition zone can be made of ordinary phosphate bricks with a body density of 2.65. Corundum mullite castable can be used at the kiln entrance.

The temperature of the rotary kiln for smelting rock ceramics is generally about 1300℃, and 2.8 body dense special phosphate bricks can be used in the firing belt, and 2.65 body dense phosphate bricks can also be used in high aluminum bricks in the transition belt. If the fuel is not natural gas, rice husks or other waste products are used as fuel, it is best to use phosphate bricks, and try not to choose high aluminum bricks.

Sludge ceramic with rotary kiln, the temperature is not high at 900℃, the whole kiln length can use 2.65 body dense ordinary phosphate brick, because this material is fired in the rotary kiln, the temperature is low and no corrosion, the whole kiln can also use three-level high aluminum brick or clay brick.

As for the refractory brick type, the brick type closest to the size can be calculated according to the size of the kiln diameter, no special provisions are required. If the brick type is designed as a fan-shaped phosphate brick, at the end of the kiln, the brick type with a thickness of 80/70 thickness and two rings of the same length and width can be squeezed at the kiln mouth. If the vertical brick is selected, each ring needs two kinds of slotted bricks of thickness and the amount of each ring is squeezed.

In short, no matter using what kind of brick type of the phosphate brick and high aluminum brick, it must be fixed with the lock joint steel plate again when reviewing the kiln.

Leave a Message

Contact Us

Email: info@chrefractory.com

TEL: +86 13721425142

At the back of the cement rotary kiln, the length of the kiln mouth is about 1 meter, wear-resistant castable can be selected, but it must have a certain degree of alkaline resistance. The castable area from 10D to the rear kiln entrance can use anti-spalling high-alumina bricks; The 7D-10D section of the rotary kiln can use silmo brick or Silmo red brick; Section 5D-7D is a transitional zone, which can use magnesia-aluminum spinel brick; The 6D-7D section can also use Silmo brick or Silmo red brick;

Phosphate brick is most suitable for use in white ash kiln, zinc kiln lining, can be used for high temperature zone and transition zone. If it is a white-ash rotary kiln, the entire kiln lining can use phosphate bricks, but it is the use of high density bricks in the high temperature zone, and the use of low density bricks in the transition zone.

Submit Request

PDF Request