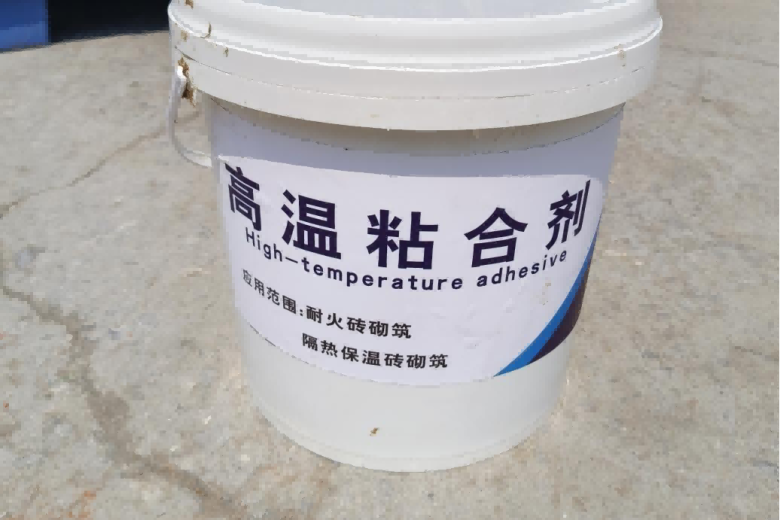

The types and functions of high temperature adhesives

Can silicon-magnesia red bricks be used as the inner lining of lithium ash kilns?

Both high alumina composite bricks and phosphate composite bricks belong to composite bricks, and the lightweight parts of the composite are both designed to protect…

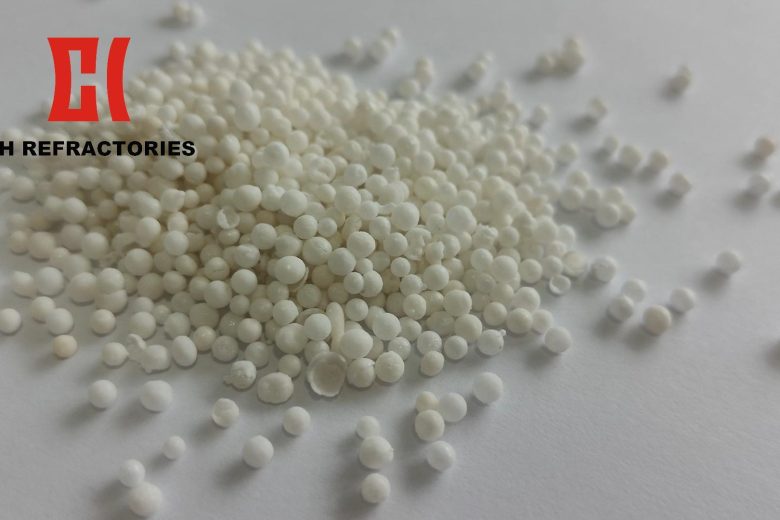

Refractory hollow balls are important raw materials for making high-grade insulating refractory materials. Compared with ordinary insulation materials, refractory hollow sphere products have the characteristics of…

The main defects in the production process of refractory bricks are underburning, overburning, damage, contamination, core encirclement, distortion, cracking, etc. Underfiring is a problem caused…

Refractory clay is the main raw material for the production of aluminosilicate refractory materials. All kinds of hard clay, soft clay, semi-soft clay and clay…

Anti-skinning castable is made by adding silicon carbide aggregates and powder to the low-cement castable, then adding high-efficiency water reducing agent and ultrafine powder, and…

Every country have different definition of refractory materials. According to international standards, refractory materials are defined as non-metallic materials and products whose chemical and physical properties…

Submit Request

PDF Request