Intermediate frequency furnace is a kind of equipment widely used in metal melting, the high temperature resistance of its lining material is directly related to the melting efficiency and the service life of the lining. So how to improve the high temperature resistance of intermediate frequency furnace lining? Improving the high temperature resistance of intermediate frequency furnace lining can extend the service life of the lining, reduce the maintenance cost and improve the production efficiency.

How to improve the high temperature resistance of intermediate frequency furnace lining

1, choose the appropriate lining material

① Refractory material

Selecting refractories with high temperature resistance is the basis of improving the high temperature resistance of lining. Materials such as high aluminum brick and magnesium brick are widely used because of their high temperature resistance, corrosion resistance and chemical erosion resistance.

② Refractory fiber material

Refractory fiber material is used as the heat insulation layer of furnace lining because of its light weight and good heat insulation performance. This material can reduce heat loss and improve the thermal efficiency of the furnace.

③ Composite refractories

Composite refractories combine the advantages of different materials, such as high refractoriness, good heat insulation performance, chemical erosion resistance, etc., can improve the comprehensive high temperature resistance of the lining.

2, optimize the lining structure design

① Multi-layer structure design

By using multi-layer structural design, materials with different properties can be used at different levels to adapt to different working conditions. For example, high-temperature resistant materials can be used for the inner layer, while insulating materials can be used for the outer layer.

② Setting of heat insulation layer

Adding insulation to the furnace lining can reduce heat transfer to the outside, keep the temperature in the furnace stable, and reduce energy consumption.

③ Reasonable determination of furnace lining thickness

The thickness of the furnace lining needs to be determined according to the working conditions of the furnace and the expected service life. Too thin can lead to premature lining damage, while too thick can increase costs and heat loss

3. Strictly control the construction process

① Construction environment control

The temperature, humidity and other conditions of the construction environment will affect the performance and construction quality of the furnace lining. For example, too much humidity can lead to a reduction in the strength of the material.

② The material is mixed evenly

In the mixing process of the lining material, it is necessary to ensure that all components are evenly mixed to avoid performance differences caused by uneven local components.

③ Standardization of construction technology

Following standardized construction processes, such as the correct pouring, compaction and curing methods, can ensure the compactness and uniformity of the furnace lining, thereby improving its high temperature resistance.

4. Maintenance and maintenance of furnace lining

① Temperature control for initial use

When the lining is used for the first time, it should be gradually heated up to avoid thermal stress and lining rupture caused by rapid heating.

② Check the lining condition regularly

Check the lining regularly, check whether the lining has cracks, falls off or other damage, and repair it in time to extend the service life of the lining.

③ Avoid overload use

Avoid leaving an intermediate frequency furnace in operation beyond its designed capacity for long periods of time, which reduces liner wear and extends its service life.

In summary, how to improve the high temperature resistance of intermediate frequency furnace lining material, through selecting suitable lining material, optimizing lining structure design, strictly controlling construction process and carrying out lining maintenance and maintenance, can improve the high temperature resistance of intermediate frequency furnace lining material. These measures help to extend the service life of the furnace lining, improve production efficiency, reduce maintenance costs, and thus bring better economic benefits.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 13721425142

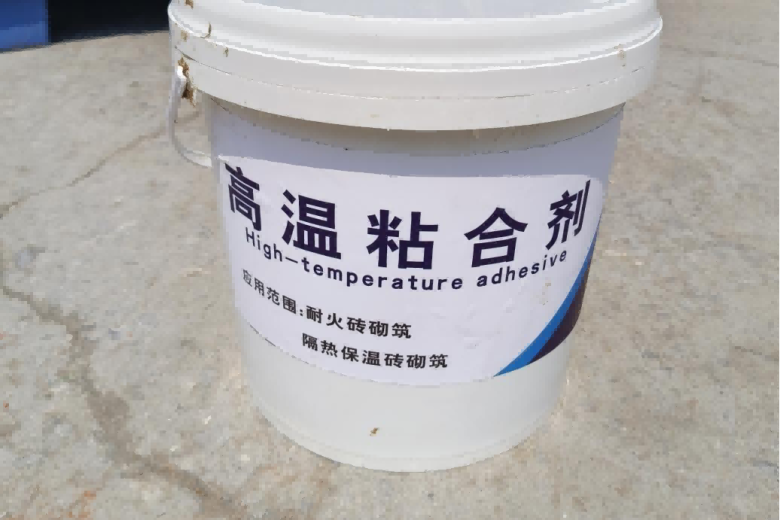

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

The light and heavy composite high alumina brick integrates the functions of the two layers of refractory bricks that need to be laid for the…

Submit Request

PDF Request